The application process for agricultural subsidies for plant protection drones

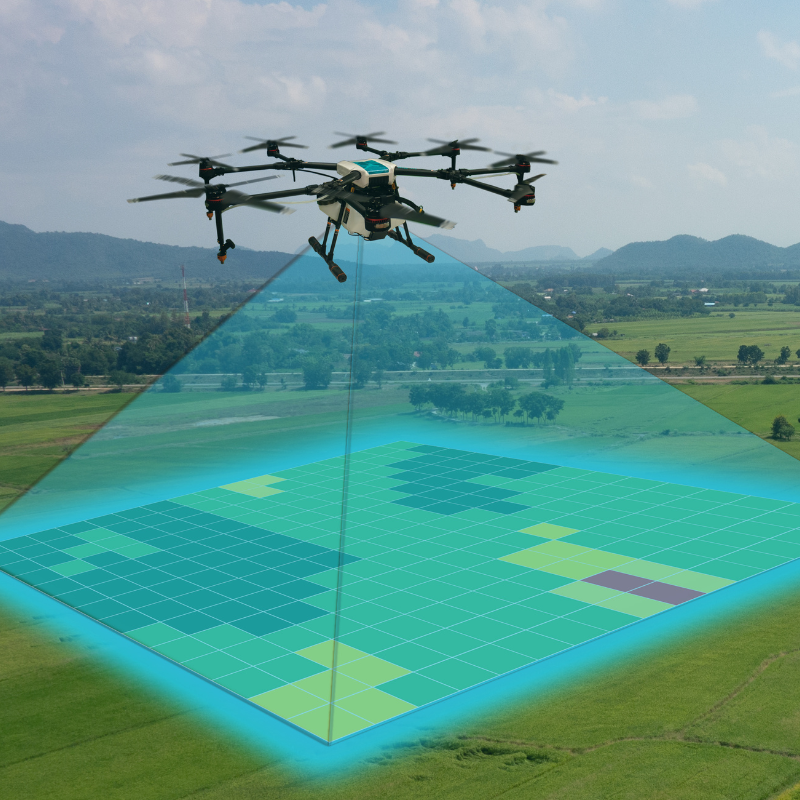

The application process for agricultural subsidies for plant protection drones Application Process for Agricultural Subsidies on Crop Protection Drones Navigating the application process for agricultural subsidies aimed at supporting the […]

The application process for agricultural subsidies for plant protection drones Read More »