Comparison: Agricultural Protection Drones vs. Manual Spraying

The shift from traditional manual spraying to drone-based applications in agriculture reflects broader trends toward efficiency, safety, and sustainability. Below is a detailed analysis of the key differences between these two methods:

1. Efficiency and Speed

- Drones

- Cover large areas (e.g., 10–50 hectares per day) in a fraction of the time required for manual labor.

- Operate continuously without breaks, adapting flight patterns to weather conditions (e.g., early mornings to avoid wind).

- Reach remote or uneven terrain (e.g., hills, forests) where ground equipment struggles.

- Manual Spraying

- Limited by human stamina and mobility, typically covering 1–2 hectares per day per worker.

- Requires frequent rest stops and is disrupted by adverse weather (e.g., rain, heat).

- Struggles with steep slopes, dense foliage, or large-scale monoculture fields.

2. Precision and Chemical Use

- Drones

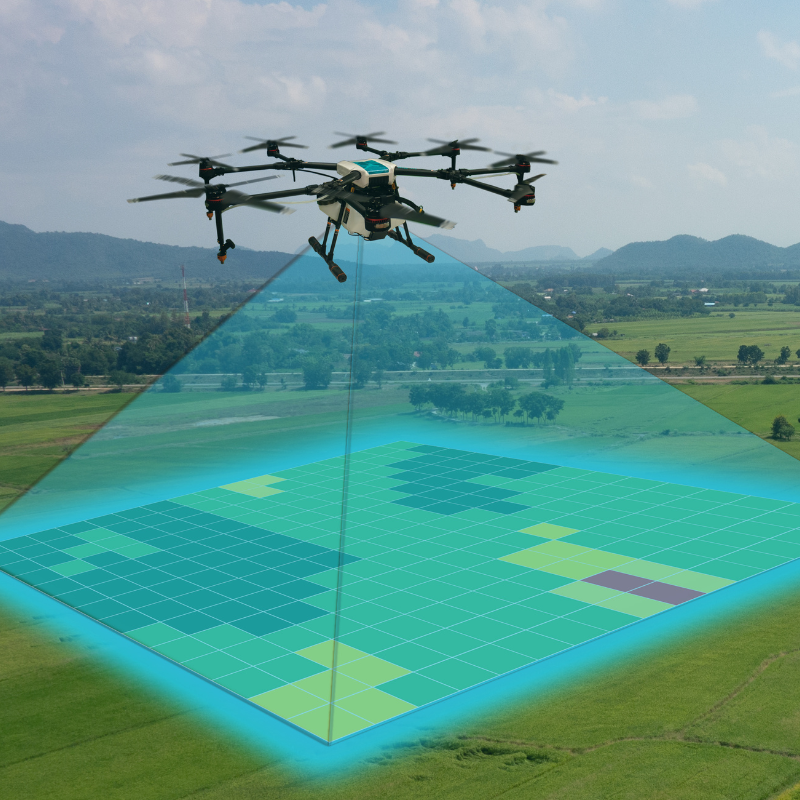

- Use GPS, AI, and multispectral sensors to apply chemicals only where needed (e.g., diseased patches, weed clusters).

- Adjust spray volume in real time based on crop density, reducing overuse by 30–50% compared to manual methods.

- Minimize drift through low-altitude flight (2–5 meters) and directional nozzles.

- Manual Spraying

- Relies on visual estimates, leading to uneven coverage and over-application in some areas.

- Prone to drift due to wind or human error, contaminating non-target zones (e.g., neighboring fields, water bodies).

- Difficult to reach tall crops or under-canopy areas without excessive chemical use.

3. Environmental Impact

- Drones

- Reduce soil compaction by avoiding heavy machinery, preserving soil structure and microbial life.

- Lower water and chemical runoff risks due to targeted application, protecting aquatic ecosystems.

- Electric drones produce zero direct emissions, cutting greenhouse gas contributions.

- Manual Spraying

- Trampling by workers can compact soil, reducing water retention and root penetration.

- Higher risk of chemical spillage or accidental contamination from backpack sprayers.

- Fossil fuel-powered ground vehicles (e.g., tractors) emit CO₂ and particulate matter.

4. Safety and Health Risks

- Drones

- Eliminate human exposure to toxic chemicals, lowering risks of respiratory diseases, skin irritation, or poisoning.

- Operate at safe distances from power lines, livestock, or hazardous terrain.

- Reduce physical strain associated with carrying heavy spray equipment.

- Manual Spraying

- Workers face prolonged exposure to pesticides, increasing long-term health hazards (e.g., Parkinson’s disease, cancers).

- Higher risk of accidents (e.g., slips, falls) in uneven fields or when handling equipment.

- Fatigue from repetitive tasks can lead to errors in mixing chemicals or calibrating sprayers.

5. Cost and Scalability

- Drones

- Initial investment in equipment and training may be higher, but long-term savings come from reduced labor, chemical, and fuel costs.

- Scalable for smallholder farms (using compact drones) or large estates (deploying fleets with automated mission planning).

- Manual Spraying

- Lower upfront costs but higher recurring expenses for labor, protective gear, and chemical waste.

- Labor shortages in rural areas can delay operations, risking crop losses.

- Less viable for large-scale farms due to time and resource constraints.

6. Data Collection and Adaptability

- Drones

- Generate real-time data on crop health, pest hotspots, and treatment efficacy, enabling data-driven decisions.

- Integrate with farm management software to track costs, optimize routes, and predict future needs.

- Adaptable to new technologies (e.g., AI-driven pest forecasting, biodegradable chemical delivery).

- Manual Spraying

- Relies on anecdotal observations, lacking quantitative data for long-term planning.

- Difficult to standardize practices across workers, leading to inconsistencies.

- Limited capacity to adopt precision agriculture tools without digital infrastructure.

7. Regulatory and Social Considerations

- Drones

- Require compliance with aviation regulations (e.g., flight altitude limits, no-fly zones) and agricultural chemical permits.

- May face public skepticism over privacy or noise concerns, though electric models mitigate the latter.

- Training programs for operators ensure adherence to safety and environmental standards.

- Manual Spraying

- Subject to pesticide handling regulations but less scrutinized for operational efficiency.

- Labor-intensive methods may perpetuate rural unemployment if not paired with upskilling initiatives.

- Community acceptance is higher in regions where traditional farming practices dominate.

Conclusion

While manual spraying remains viable for small-scale, low-tech operations, agricultural protection drones offer unparalleled advantages in efficiency, precision, and sustainability. Their ability to reduce chemical waste, protect worker health, and adapt to evolving farming needs positions them as a cornerstone of modern green agriculture. However, the transition must balance technological adoption with equitable access, ensuring smallholders and remote communities benefit equally. As regulations and training frameworks evolve, drones will likely become indispensable tools for feeding a growing global population while safeguarding the planet.