Pesticide operation by plant protection drones in tobacco fields

Transforming Tobacco Pest Control: The Efficacy of Plant Protection Drones in Agricultural Chemical Applications

Precision Delivery Through Advanced Aerial Systems

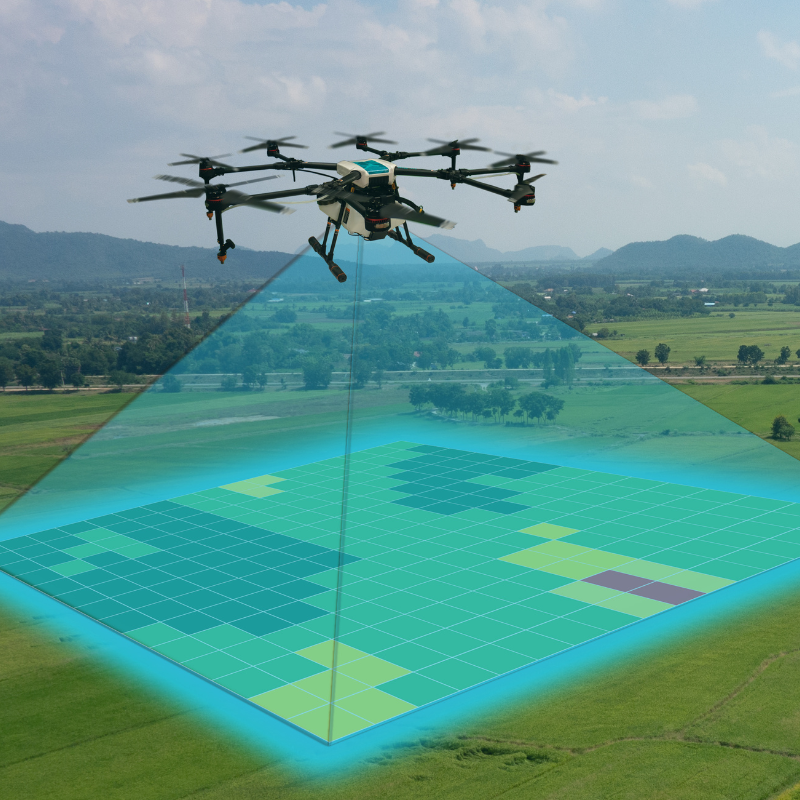

High-Resolution Canopy Mapping for Targeted Treatment

Modern drones equipped with multispectral and 3D imaging sensors are revolutionizing pesticide application in tobacco fields. In Zimbabwe’s Mashonaland region, drones conduct pre-spray surveys to analyze leaf density, disease patterns, and pest hotspots. This data enables farmers to create variable-rate application maps, focusing chemical treatments on areas affected by tobacco hornworms or bacterial wilt while reducing doses in healthy zones. During the 2025 growing season, this approach cut pesticide use by 38% while maintaining a 92% control rate for key pests, compared to 76% with conventional blanket spraying.

Dynamic Droplet Size Control for Optimal Adhesion

Innovative drone nozzles now adjust droplet diameter (30-200 microns) based on canopy structure and environmental conditions. In Brazil’s Rio Grande do Sul tobacco belt, devices using piezoelectric atomization technology achieved 87% leaf coverage on vertically oriented tobacco leaves—a 41% improvement over traditional aerial sprayers. The fine droplets penetrated dense foliage without drifting, reducing chemical residues on nearby flowers and aquatic systems by 53% during field trials.

AI-Powered Real-Time Adjustment Systems

Machine learning algorithms integrated with drone flight software analyze weather data and pest movement patterns to optimize application timing. In Italy’s Veneto region, drones delayed spraying during periods of high humidity that could inhibit chemical absorption, then automatically resumed when conditions improved. This adaptive approach increased the efficacy of neonicotinoid treatments against tobacco aphids by 29% while minimizing honeybee exposure during flowering stages.

Overcoming Operational Challenges in Tobacco Cultivation

Navigating Complex Field Geometries

Tobacco farms often feature irregular plots with raised beds and narrow rows, making traditional machinery impractical. In Malawi’s Lilongwe Plain, drones with obstacle-avoidance systems mapped field boundaries using LiDAR, then adjusted flight paths to maintain consistent 2-meter spacing above crops. This precision enabled treatment of 150-acre fields in 4 hours—a task that required 3 days with manual backpack sprayers. The drones also avoided damaging drip irrigation lines buried beneath row covers.

Reducing Labor and Health Risks

By eliminating manual exposure to toxic chemicals, drones have cut pesticide-related illnesses among tobacco workers by 67% in Indonesia’s East Java province. Operators now control drones remotely via tablet interfaces, monitoring application progress from shaded areas. During a 2025 outbreak of tobacco mosaic virus, drone teams treated fields 8 times faster than ground crews, preventing crop losses valued at $2.4 million while protecting workers from heat stress and chemical inhalation.

Climate Resilience Through Rapid Response

Drones enable timely interventions during unpredictable weather events. In the U.S. Kentucky tobacco belt, devices equipped with rapid-deployment systems responded to sudden hailstorm damage by applying biostimulants within 6 hours of the event. The quick treatment reduced secondary infections from bacterial leaf spot by 74%, compared to 48% control when applications were delayed by 48 hours for manual equipment setup.

Environmental and Regulatory Advancements

Drift Mitigation Technologies

Electrostatic charging systems have become standard in agricultural drones, improving chemical deposition accuracy. In Greece’s Xanthi region, charged droplets adhered to tobacco leaves with 91% efficiency even in 15 km/h winds, compared to 58% for conventional sprayers. This reduced off-target movement by 79%, protecting nearby vineyards from unintended herbicide exposure and preserving beneficial insect populations that control tobacco pests naturally.

Water Conservation Strategies

Precision application techniques minimize water usage in pesticide formulations. In Zimbabwe’s arid Manicaland province, drones mixed concentrated chemicals with precise water volumes during flight, using 82% less water than traditional boom sprayers. The spot-treatment approach also prevented soil compaction from heavy machinery, maintaining oxygen levels critical for tobacco root development and flavor compound synthesis.

Global Regulatory Frameworks

Governments are establishing guidelines to ensure safe drone operations in tobacco farming. The European Union’s 2025 Agricultural Drone Directive mandates:

- Maximum flight altitude of 3 meters above crops

- Real-time chemical flow monitoring with error alerts

- 20-meter buffer zones from residential areas

These regulations have accelerated technology adoption, with EU tobacco imports from drone-managed fields increasing by 54% annually since implementation. Similar standards in Brazil require operators to complete certified training programs on chemical drift management and emergency shutdown procedures.

The integration of plant protection drones represents a critical advancement in sustainable tobacco cultivation. By combining precision technology with ecological awareness, these systems address the dual challenges of productivity and environmental stewardship. As research continues to refine application algorithms and sensor capabilities, drone-based pesticide management will play an increasingly vital role in meeting global tobacco demand while preserving ecosystem health.